BEI Sensors M5060TB1600 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M5060TB400 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M5060TB600 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M5060THC1000 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M5060THC1200 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M5060THC1400 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M5060THC1600 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M5060THC400 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M5060THC600 Relé

Features

- High Surge Current Rectifier Circuits

- 5 Different Circuits to Choose from

- Up to 1600 Volt Blocking Standard

- UL Recognized E72445

BEI Sensors M9105/XXX Codificador

Features

The 8810/013 Rare Earth Magnet allows users to build their own magnet holder assembly for use with ACW4 and TCW4 sensors. The M9105 series of magnet holders are designed to make mounting and alignment of the magnet to its sensor assembly easy to accomplish.- Three different mounting systems are available.

- Mount directly to the shaft with a variety of shaft diameters such as 6mm with female magnet support M1905/K06

- Mount directly into a 10mm bore with male magnet support M9105/M10-01 or use a two-hole front mount magnet support M9105/F26

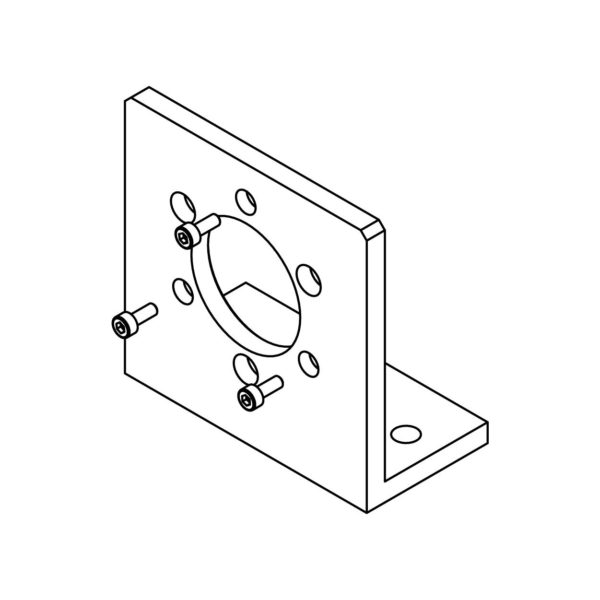

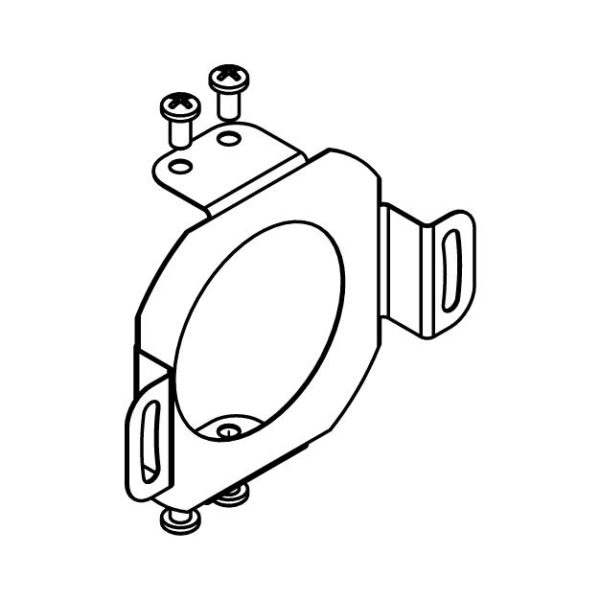

BEI Sensors M9202 Codificador

Features

- Secure Mounting for MHM5 model Multi-turn Absolute

- Center hole uses MHM pilot to ensure precise location.

- Attaches with 3 X M3 or 3 X M4 Cap Head Mounting screws.

- Maintains perpendicularity of shaft to mounting faceplate

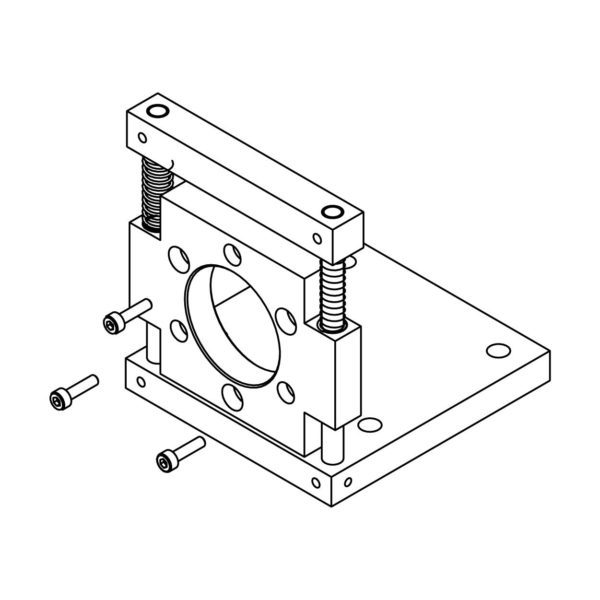

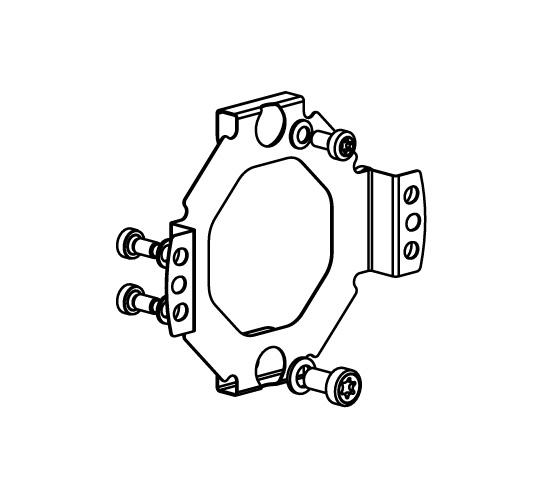

BEI Sensors M9212-01 Codificador

Features

- All aluminum construction

- Provides solid mounting platform for MHM5 with a measuring wheel

- 36mm pilot ensures concentric mounting of encoder.

- Dual springs allow for up to 8mm total travel

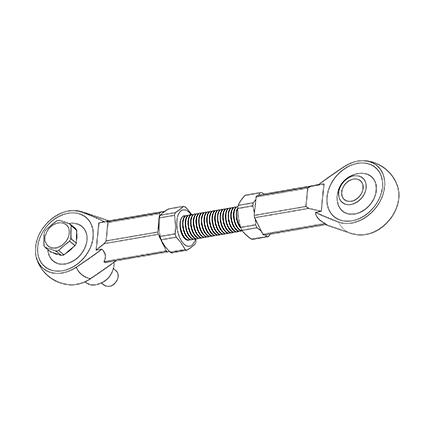

BEI Sensors M9230-03/XXX Codificador

Features

- Swiveling ball ends compensate for movement due to shaft runout and axial motion while keeping the body of the encoder from rotating

- The threaded rod and locknuts make this tether somewhat adjustable in length, making it useful for a wider range of applications

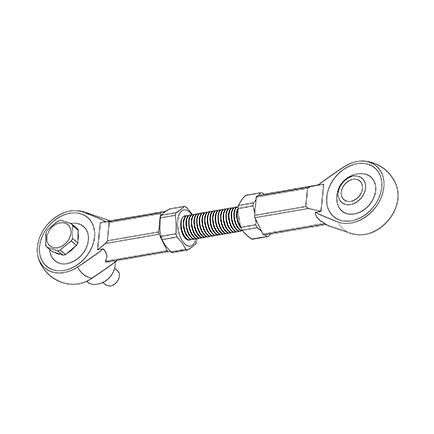

BEI Sensors M9230-04/XXX Codificador

Features

- This threaded rod tether has swiveling ball ends that compensate for movement due to shaft runout and axial motion while keeping the body of the encoder from rotating.

- The threaded rod and locknuts make this ball end tether somewhat adjustable in length, so it can be used in a wide range of applications.

- Maximum misalignments are as described below and shown in the illustration.

BEI Sensors M9301/196 Codificador

Downloads

- Installation Kit MAAX Datasheet

- M033_M9301_196 PDF Datasheet

- M033_M9301_196 STEP Drawing

- M033_M9301_196 DWG Drawing

BEI Sensors M9410/009-XX Codificador

Features

- Integrated Couplings allow the user to reduce the bore size of the LP35 Series encoders from 30mm down to a size that matches to their mating shaft.

- The coupling provides both thermal and electrical isolation of the encoder from the shaft without increasing the overall thickness of the encoder.

- Since it also provides flexibility against shaft runout, the body of the encoder can be hard mounted to the motor frame or flange.

- Note the limits on misalignment in the table, below.

BEI Sensors M9410/010-XXX Codificador

Features

- The integrated coupling allows for hard mounting of the encoder body to the motor frame or flange

- Provides both thermal and electrical isolation of the encoder from the shaft without increasing the overall thickness of the encoder

- Available in several bore sizes to fit many shaft sizes

BEI Sensors M9410/011-XX Codificador

Features

- Integrated couplings allow the user to reduce the bore size of the encoder from 30mm down to a size that matches their mating shaft

- Provides both thermal and electrical isolation of the encoder from the shaft without increasing the overall thickness of the encoder

- Available in several bore sizes to fit many shaft sizes

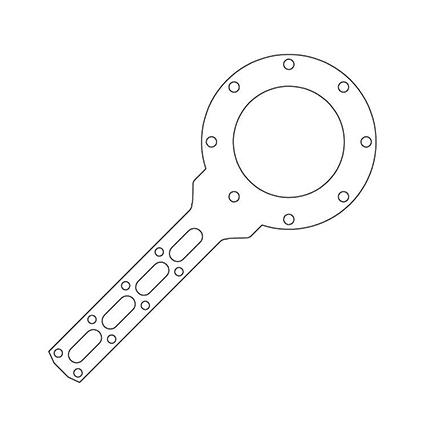

BEI Sensors M9445/017 Codificador

Features

- Flexmount kit comes with all hardware for installation on the encoder.

- Works with MHK5 (Blind Shaft Style) multi-turn absolute encoder

- Stainless steel for corrosion resistance

- Fits on all diameters of blind shaft

- See Dimension Drawing, below

- Slotted mounting allows for rotational orientation of encoder

BEI Sensors M9445/044 Codificador

Features

- Flexmounts are specially designed to work with Hollow Shaft versions of the SIL 3 safety encoders. Do not attempt to replace with any other mount that is not certified for this use. When ordered as part of the model number (DX** for the DSO5 and DW** for the DSU9) they will come installed on the encoders.

- Flexmounts can also be ordered separately as kits that include the mounting hardware. Use the part numbers as indicated in the above drawings: M9445/044 for the DSO5 and M9445/045 for the DSU9

BEI Sensors M9445/045 Codificador

Features

- Flexmounts are specially designed to work with Hollow Shaft versions of the SIL 3 safety encoders. Do not attempt to replace with any other mount that is not certified for this use. When ordered as part of the model number (DX** for the DSO5 and DW** for the DSU9) they will come installed on the encoders.

- Flexmounts can also be ordered separately as kits that include the mounting hardware. Use the part numbers as indicated in the above drawings: M9445/044 for the DSO5 and M9445/045 for the DSU9

BEI Sensors M9445/046 Codificador

Downloads

- accessory tether arm kit dso5-DSU9 datasheet

- accessory tether arm kit m8 dsu9 step drawing

- accessory tether arm kit m8 dsu9 PDF drawing

- accessory tether arm kit m8 dsu9 DWG drawing

BEI Sensors M9445/047 Codificador

Downloads

- accessory tether arm kit dso5-DSU9 datasheet

- accessory tether arm kit m6 dso5 Step Drawing

- accessory tether arm kit m6 dso5 PDF Drawing

- accessory tether arm kit m6 dso5 DWG Drawing

BEI Sensors M9445/063 Codificador

Downloads

- DSO5, DST5, DSK5, DSU9 Accessory Flex Mount Kit Datasheet

- DST51x M9945/063 Stator Coupling PDF Drawing

- DST51x M9945/063 Stator Coupling STEP Drawing

- DST51x M9945/063 Stator Coupling DWG Drawing